Type a search term to find related articles by LIMS subject matter experts gathered from the most trusted and dynamic collaboration tools in the laboratory informatics industry.

A Lindlar catalyst is a heterogeneous catalyst consisting of palladium deposited on calcium carbonate or barium sulfate then poisoned with various forms of lead or sulfur. It is used for the hydrogenation of alkynes to alkenes (i.e. without further reduction into alkanes). It is named after its inventor Herbert Lindlar, who discovered it in 1952.

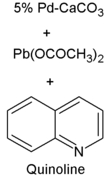

Lindlar catalyst is commercially available but can also be created by reducing palladium chloride in a slurry of calcium carbonate (CaCO3) and adding lead acetate.[1][2] A variety of other "catalyst poisons" have been used, including lead oxide and quinoline.[3] The palladium content of the supported catalyst is usually 5% by weight.

The catalyst is used for the hydrogenation of alkynes to alkenes (i.e. without further reduction into alkanes). The lead serves to deactivate the palladium sites, and further deactivation of the catalyst with quinoline or 3,6-dithia-1,8-octanediol enhances its selectivity, preventing formation of alkanes. Thus if a compound contains a double bond as well as a triple bond, only the triple bond is reduced. An example being the reduction of phenylacetylene to styrene.

Alkyne hydrogenation is stereospecific, occurring via syn addition to give the cis-alkene.[4] For example the hydrogenation of acetylenedicarboxylic acid using Lindlar catalyst gives maleic acid rather than fumaric acid.

An example of commercial use is the organic synthesis of vitamin A which involves an alkyne reduction with the Lindlar catalyst. These catalysts are also used in the synthesis of dihydrovitamin K1.[5]